In the context of social development, the urbanization process is gradually accelerating. In order to meet the needs of power transmission and transformation projects, power cables are widely used.

The main factors of cable accessory failure usually include: damage to cable joints and cable terminals.

If they cannot be solved in time, it will cause serious impact. For cable joints, their operational stability is only five to ten years.

Thereafter, they will be affected by operating conditions, environmental factors and human factors, which will lead to aging and deterioration of cable glands, thus reducing the quality of work. Therefore, the search for new solutions is of great importance at this stage in the work of power companies.

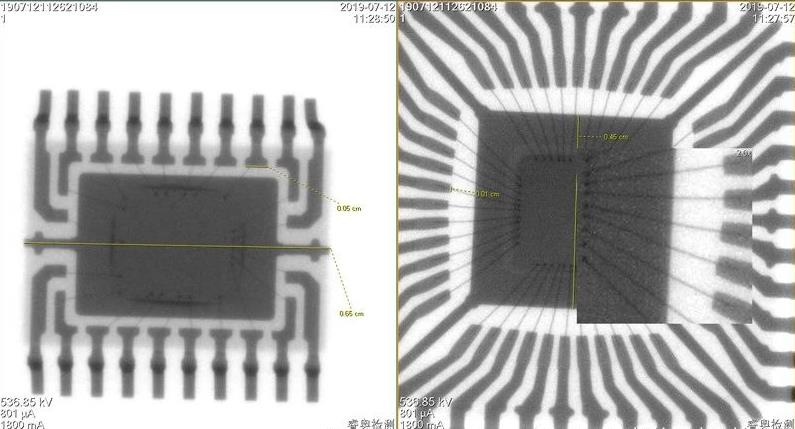

Through the application of X-ray inspection technology, the defects, location and size of cable joints can be accurately determined, and the accuracy of fault detection, inspection quality and inspection efficiency can be improved, thus providing effective support for the operation and development of the cables, and fully meeting the core requirements of modernization on the detection of cable faults in power companies.

Today, X-RAY can check the project is also very colorful, such as electronic components, BGA, electronic equipment components, LED components, metal composites and plastic materials, such as in the BGA casting exists for example, empty welding, etc., it can also accurately and quickly differentiate between, but also for the encapsulated components and microelectronic systems to carry out a detailed inspection and analysis.