NDT non-destructive testing industry has a history of several decades in China. With the development of social economy, NDT industry has been involved in all aspects of people's life. Some experts once said that NDT is a vigorous industry, and this industry has a lot of space for development, especially in China, with a very broad development prospect.

NDT NDT equipment can be broadly categorized into 26 categories with more than 1,000 specific product models and varieties. In general, it covers most of the current domestic NDT NDT technology applications, especially for routine NDT equipment, devices, accessories, consumables and so on. Basically, it has realized low price and high quality, and can meet the inspection needs of various industrial fields.

For example, portable ultrasonic flaw detector and analog ultrasonic flaw detector, digital ultrasonic thickness gauge, ultrasonic testing standard test block, ultrasonic probe, X-ray flaw detector, various radiographic auxiliary inspection equipment, portable eddy current testing equipment, large eddy current testing automation equipment systems, etc.

1. Ultrasonic testing equipment: digital and analog universal portable ultrasonic flaw detector, large-scale automated ultrasonic flaw detection system (pipe, bar, plate, welded pipe, etc.), a variety of special testing equipment (ductile iron spheroidizer, bolt tightness tester, sound velocity meter, ceramic insulators ultrasonic tester, etc.), a variety of general and special ultrasonic probe, ultrasonic thickness gauge, TOFD ultrasonic flaw detector, phased array Ultrasonic Flaw Detector, Phased Array Ultrasonic Flaw Detector, etc.

2. Magnetic particle flaw detection equipment and materials: general portable, mobile, lathe-type magnetic particle flaw detection equipment, a variety of special magnetic particle flaw detection equipment, large-scale semi-automatic and automated magnetic particle flaw detection system, pulse magnetization equipment, demagnetization machine, auxiliary tools and consumables. The use of rotating magnetic fields, composite magnetization and fluorescent magnetic particle inspection methods is becoming increasingly common. Automatic crawling devices for magnetic particle inspection using CCD camera recording and automatic fluorescent magnetic particle inspection systems have been put on the market.

3. Penetration test equipment and materials: used to meet the different sensitivity levels (general industrial grade to nuclear industrial grade special materials) color penetration, fluorescence penetration, color fluorescence penetration of materials, portable equipment (such as spray cans), large-scale automated penetration of the assembly line system, a variety of auxiliary equipment and equipment.

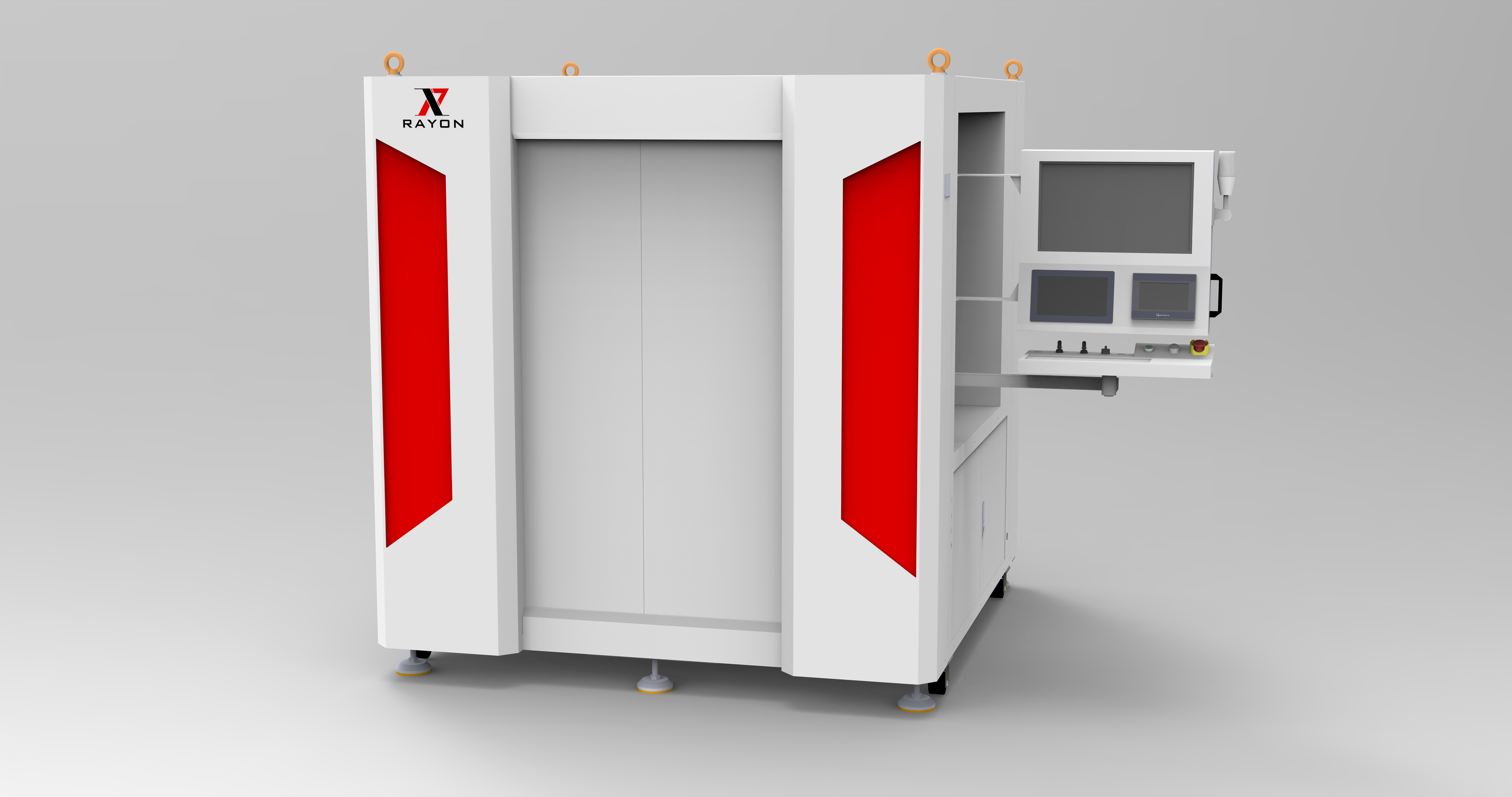

4. Ray detection equipment: X-rays, γ-rays, β-rays, neutron rays, high-energy X-rays, X-ray tubes, general-purpose portable, mobile, large-scale stationary ray detection equipment, frequency control, constant frequency, constant potential X-ray machine, auxiliary equipment, a variety of radiation protection equipment and devices, a variety of radioisotope sources.

5. Eddy current detection equipment: general portable digital eddy current detector, pulse eddy current detection system, array eddy current detection system, large-scale automatic eddy current detection system, a variety of special eddy current detection equipment, supporting a variety of eddy current sensors, coating thickness gauge, supporting auxiliary equipment, material sorting instrument, conductivity tester, hardness sorting instrument, metal detector, wire rope tension tester, wire rope detector, etc.

6. Magnetic leakage detection equipment: general-purpose, special-purpose, large-scale automatic magnetic leakage detection system.

7. Endoscopes: optical endoscopes, fiber-optic endoscopes, video endoscopes.

8. Optical measuring instruments: white light meter, black light meter, ultraviolet intensity meter, fluorescence meter, etc.

9. Acoustic emission test equipment: portable portable systems and large systems of multi-channel acoustic emission testing.

10. Leak detection equipment: EDM leak detector, intelligent acoustic pulse rapid leak detector, pipeline leakage detector and locator, organic inert fluorescent tracer leakage detection products, penetration leakage detection fluid, underground pipeline leakage detector, underground cable detection leakage detector, pipeline locator, natural gas pipeline leakage detector, wet coating leakage detector and so on.

11. Hardness measuring instruments: Richter hardness tester, ultrasonic hardness tester.

12. Electromagnetic ultrasonic flaw detection equipment: electromagnetic ultrasonic flaw detection system, automatic electromagnetic ultrasonic flaw detection system, electromagnetic ultrasonic thickness gauge.

13. X-ray real-time imaging and industrial CT equipment: the use of image-enhanced, DR-type conventional equipment, specialized equipment, resolution test card.

14. Laser inspection equipment: portable laser electron scattering instrument, using laser digital scattering interference technology of large-scale automatic tire nondestructive testing system, laser material thickness online measuring instrument, online laser diameter measurement instrument, laser digital detector, laser ultrasonic inspection system, holographic photographic film and dry plate, etc.

15.Potential method crack depth measuring instrument.

16. Infrared detection equipment: infrared thermometer, infrared endoscope, infrared thermal imaging camera.

17. Various series of standard test blocks, sensitivity test blocks and test blocks, general comparative test blocks, special comparative test blocks, etc. for various non-destructive testing methods.

18. A variety of special mechanical aids and systems for non-destructive testing applications: mechanical equipment for semi-automatic and automatic flaw detection systems, pipeline tracks for radiographic testing, test block scrapers, commercial X-ray machines, fixed fixtures and brackets, lifting trucks in, etc.

19. With phosphor, UV lamp and black light source for fluorescence penetration testing.

20. Testing equipment for rock, concrete, pile foundation, concrete rebar tester, digital rebound hammer, rebar position tester, floor thickness tester, wave velocity logging meter, etc.

21. Microwave testing system, terahertz wave testing system.

22.Thermoelectric metal material sorter.

23.Magnetic stress tester.

24. X-ray stress tester, X-ray diffractometer.

25. Metal magnetic memory technology: intelligent magnetic memory metal detector, stress concentration magnetic detector, crack magnetic indicator.

26. Others: such as surface roughness meter, vibration meter, residual stress tester, ultrasonic concentration meter, ultrasonic flow meter, ultrasonic liquid level meter, ceramic