1.Overview of X-RAY Inspection

As one of the five conventional non-destructive testing methods, X-RAY testing technology has been widely used in industry. According to the definition of modern industrial commodity categories, ray-based testing is divided into three main categories: photographic testing, real-time imaging testing, and tomography.

In fact, there is no difference between X-rays and natural light in nature, they all belong to electromagnetic waves, but the energy of X-ray quantum is much larger than that of visible light, which can penetrate the objects that cannot be penetrated by visible light, and can have complex physical and chemical effects with substances.

2. Principle of X-RAY test

X-rays can penetrate materials that cannot be penetrated by ordinary visible light. The penetration ability is related to the wavelength of X-rays and the density and thickness of the penetrating material. To summarize, the shorter the wavelength of X-rays, the higher the penetration rate; the lower the density and the thinner the thickness, the easier the X-rays penetrate.

When a substance absorbs X-rays or other rays (e.g., gamma rays), the molecules that make up the substance are broken down into positive and negative ions, which is called ionization. The number of ions is proportional to the amount of X-rays absorbed by the substance, which can be calculated by measuring the ionization of air or other substances.

The basic principle of X-ray imaging is based on the properties of X-rays and the differences in density and thickness of parts.

3. Types of applications of X-RAY inspection technology

1, medical testing: X-RAY equipment can be used for human body fluoroscopy detection X-ray film, CT, etc., tumor radiation therapy.

2, quality inspection: X-RAY equipment can be used to detect defects in the casting and welding process (industrial, electronic and other industries are available).

3、Thickness Measurement: X-RAY equipment can be used for online, real-time, non-contact thickness measurement.

4, elemental detection: X-RAY equipment can be used for material elemental composition testing, analysis (such as ROHS testing, etc.).

5、Security inspection: X-RAY equipment can be used in the field of public safety for security checks.

6, dynamic research: X-RAY equipment can be used to study the dynamic process, such as ballistics, explosions, casting technology.

4. The advantages of X-ray inspection technology

Can be non-destructive testing, that is, will not damage the inspected object, convenient and practical. At the same time, can realize other detection methods can not realize the unique detection effect. In terms of real-time imaging X-RAY equipment, through the detector will detect the data transmission to the computer display, after the software processing, real-time imaging shows the test results, intuitive and clear, easy to operate, easy to save, traceable.

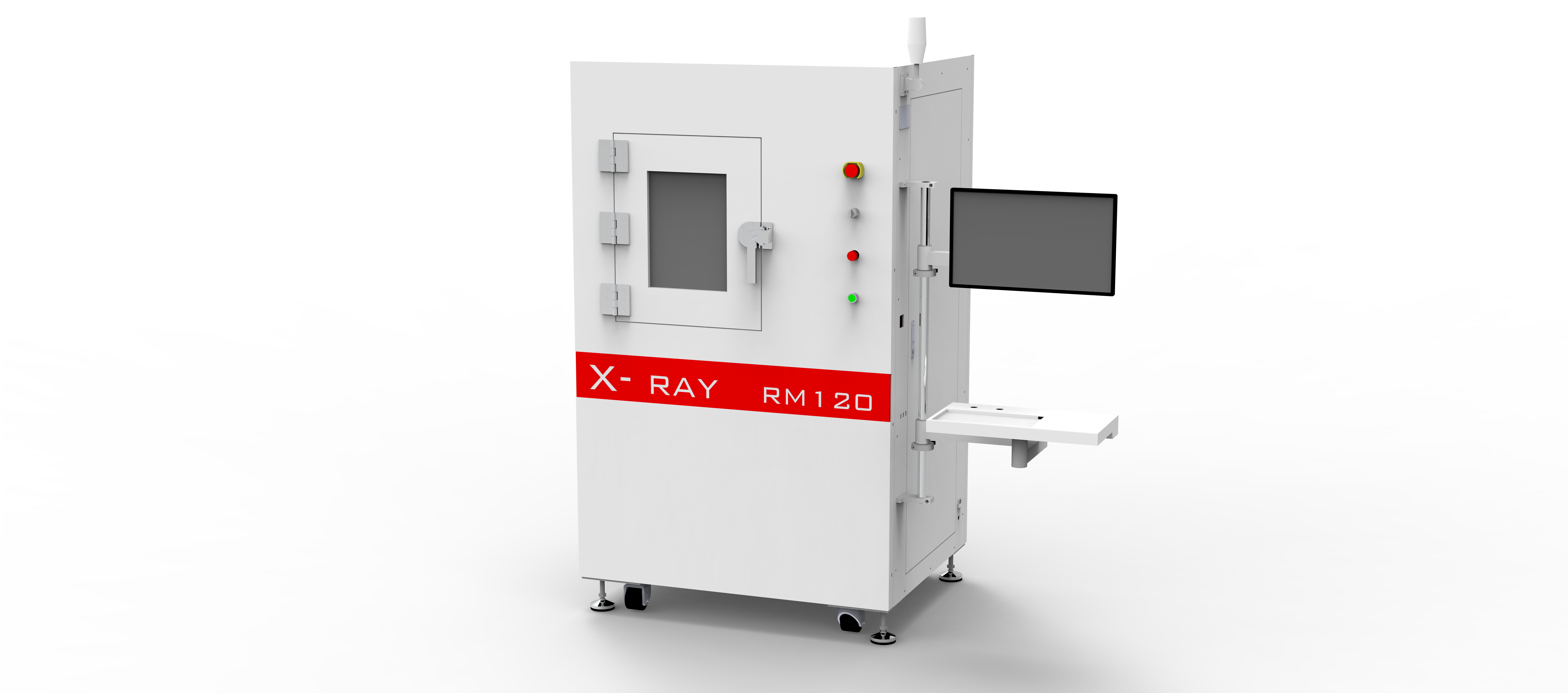

5. Non-destructive testing equipment recommendations

RAYON is a high-tech enterprise engaged in precision X-ray technology research and X-ray inspection equipment development and manufacturing. The company's products are widely used in electronic product manufacturing, metal casting industry, rubber, plastic, composite materials, food, daily chemical manufacturing, children's toys manufacturing, bags, shoes manufacturing, pressure vessels, pressure piping, steel structures, mechanical components, industrial equipment, transportation facilities, petroleum and petrochemical, electric power equipment, shipbuilding, automobile manufacturing, universities and scientific research and other fields.

In addition, RAYON also provides customers with free sample testing services and a variety of non-standard customized products and solutions to maximize customer satisfaction, is the best choice of X-RAY inspection equipment.

Translated with DeepL.com (free version)