With the help of advanced technology and instrumentation, non-destructive testing (NDT) technology can, without damaging or altering the idealized state of the object to be tested, carry out highly sensitive and reliable inspection and testing of the structure, nature and state of the object to be tested, so as to judge their continuity, integrity, safety and other performance indexes.

As an effective means of inspection, X-ray non-destructive testing has been applied to countless products as follows:

I. Metal/plastic/encapsulation (die-casting parts, injection molding parts, plastic parts, automotive parts, ceramic parts for high-voltage electrical appliances, foodstuffs, bags, children's toys ......);

II. Connectors/connections (plugs, sockets, wiring, wire connectors, connector soldering, USB, HDMI, IEEE, FPC, VGA ......);

Third, electronic components (LED, PCB, BGA, IC components, fuses, electric fuses, capacitors and resistors, sensors, micro switches ......)

However, as the scale of industrial production continues to expand, the requirements for X-ray inspection equipment also continue to improve.

Many traditional X-ray film inspection and real-time imaging offline inspection can not meet the needs of contemporary industrial sound.

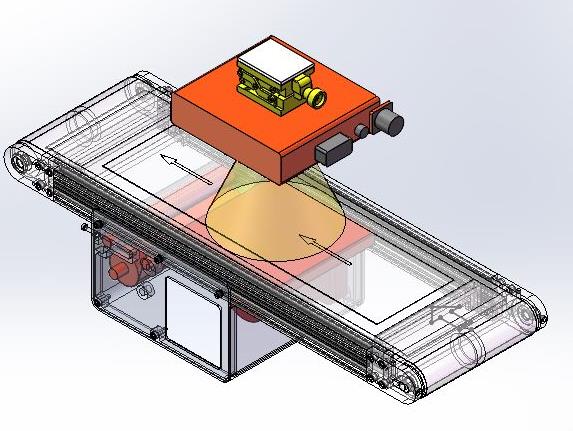

This has led to the introduction of on-line X-ray inspection equipment, which improves productivity, reduces labor costs, high automatic identification of part defects, a high degree of automation, and is implemented in tandem with the part manufacturing process.

Non-standard customization and automation solutions

01.Development of customized solutions

Technical team based on customer information, test data, comprehensive use of industry experience and X-ray hardware characteristics of the various parts, to give recommendations and practical testing, including software engineering data acquisition and a series of advanced technologies, to discuss customized solutions for customers to design and provide targeted digital imaging inspection system solutions.

02.Planning and implementation of the project

Tailored for customers to control costs (pre-investment, late operation), equipment engineering with cost-effective fully consider the practicality of the detection system and advanced, to avoid the possibility of human factors caused by the leakage of detection, reduce the operator's labor intensity. Ensure that the system runs more reliable and stable, more powerful.

03. Well-designed manufacturing

High detection efficiency and reliability for the purpose of designing the transmission machinery and Rui Ao detection of one-button automatic detection and control methods to meet the majority of industrial areas, to achieve the purpose of replacing the film photographic method to improve detection efficiency, productivity, reduce detection costs, reduce labor intensity, in the use of safety and security, to avoid misdirection caused by improper operation of the leakage of detection occurs.

04.Installation, commissioning, training

Modular production, research into the field conditions, saving time on-site construction;

ISO9001 standardized workflow, strict implementation of the process;

Professional project installation team to execute on-site management;

Meticulous and patient training courses to ensure that each operator is skillful in operating the detection system.

05.Maintenance and repair services

1 year warranty, 10 years of service;

24-hour WeChat and mobile online service;

Problems, 2-hour response within the province, super-fast processing speed;

Regular maintenance reminders, with network thinking to provide you with value-added services.